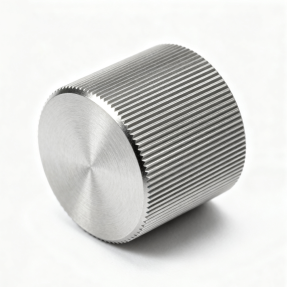

①Pre-treatment Requirements

Diameter Reduction:

Before knurling, the workpiece diameter needs to be reduced by approximately (0.8~1.6) × module m to

allow for the raised pattern.

Surface Roughness:

Ra ≤ 12.5μm; excessive roughness can lead to blurred patterns.

②Processing parameter settings

| Parameter |

Recommended Value |

Explanation |

| Cutting speed |

5~10 m/min |

Too high a feed rate leads to vibration, while too low a feed rate results in insufficient

compression. |

| Feed rate |

0.3~0.6 mm/r |

A large feed rate ensures clear pattern formation. |

| Coolant |

Cutting oil / emulsion |

It also reduces friction and surface scratches. |

③Operation Procedure

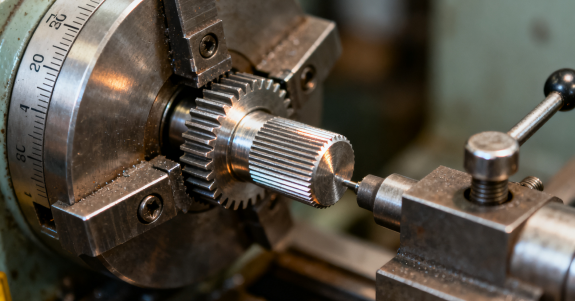

Workpiece Clamping:

Minimize the overhang length; use a tailstock to support long workpieces.

Tool Centering:

Align the center of the knurling cutter with the center of the spindle; the initial contact width should

be 1/3 to 1/2 of the roller width.

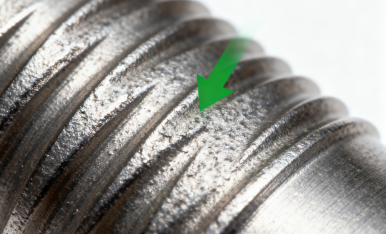

Layered Rolling:

Gradually apply pressure in 2-3 stages, with the highest pressure applied initially, until the pattern

is fully formed.

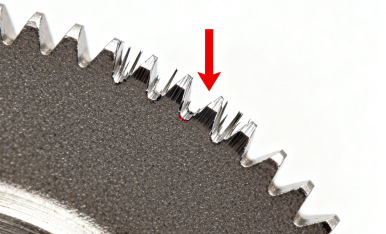

Deburring:

Chamfer the workpiece end face at a 45° angle to the root of the pattern, removing any burrs.

④CNC Programming Techniques

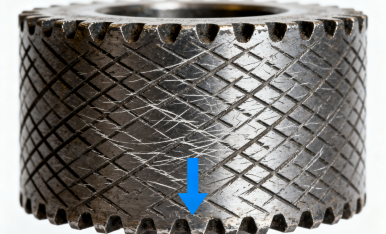

Rhombus Pattern Machining

The double-ended thread command can be used to simulate the overlapping effect of positive and negative

threads:

G32 Z-50. F40. Q0; Right-hand thread

G32 Z-50. F40. Q180000; Left-hand thread

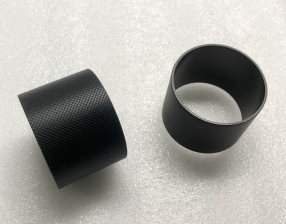

Straight grain machining

Using spindle locking (M50), grooves are broached along the Z direction. The smaller the index value, the

denser the texture.