Your Trusted CNC Partner for Every Industry

Finding a supplier that truly understands your requirements can be challenging. That's why we focus on fast response, transparent communication, and strict quality checks at every stage.

With over a decade of expertise in precision CNC machining, we deliver custom solutions tailored to the unique needs of each industry. Our commitment to quality, reliability, and innovation ensures that every project meets the highest standards.

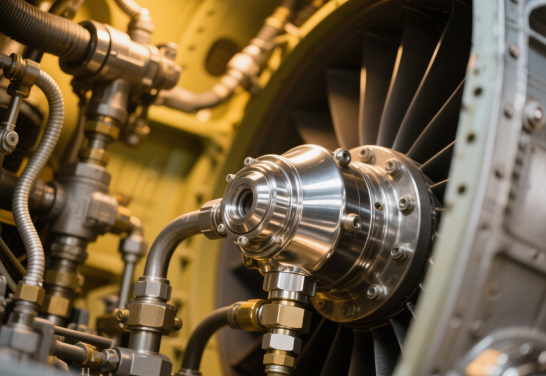

With over years of experience in the aerospace sector, we specialize in delivering high-precision components that meet the rigorous standards of aerospace applications. Our CNC machining expertise ensures parts are produced with exceptional accuracy and can withstand extreme temperatures and pressures. We work closely with clients to develop customized solutions that enhance performance, reliability, and safety in even the most demanding conditions.

Learn More

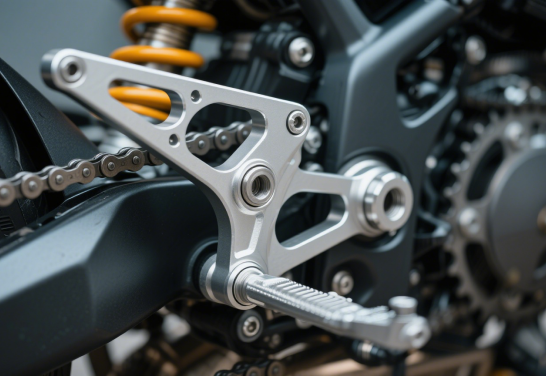

With years of experience in the motorcycle industry, we specialize in producing lightweight, high-performance components designed to meet the exacting standards of motorcycle manufacturers and enthusiasts. Our CNC machining capabilities allow for highly precise production of parts that are critical for performance, from engine components to suspension systems. We offer tailored solutions that ensure the strength, durability, and precision required for motorcycles to perform optimally in extreme conditions.

Learn More

Custom CNC parts for high-end bicycles, combining lightweight materials and tight tolerances to enhance durability and riding performance.

Learn More

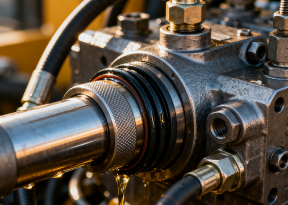

High-strength, leak-proof CNC components for hydraulic systems, built to withstand extreme pressure and ensure long-term stability.

Learn More

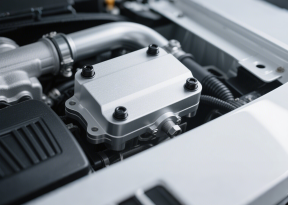

Precision CNC machining for automotive components, ensuring high performance, tight tolerances, and reliability for both prototype and mass production parts.

Learn More

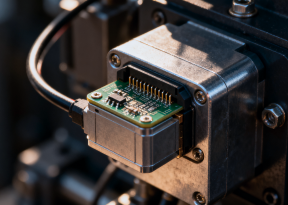

Precision-machined housings and components for various sensors, supporting reliable performance in aerospace, automotive, and medical applications.

Learn More

Finding a supplier that truly understands your requirements can be challenging. That's why we focus on fast response, transparent communication, and strict quality checks at every stage.

With years of experience serving aerospace, automotive, Bicycles, motorcycles, and hydraulics industries, REKO understands the unique standards and requirements of each field. Every project follows a strict quality management system to ensure precision, consistency, and reliability.

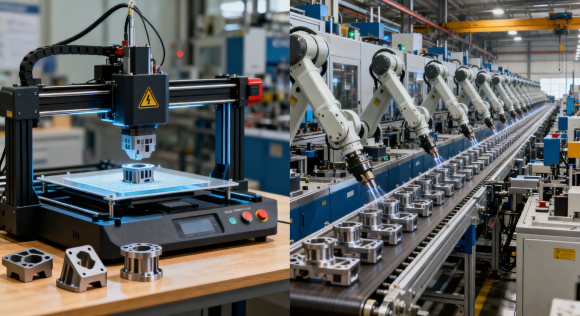

From rapid prototyping to large-scale production, we offer flexible manufacturing solutions. Whether you need a few custom parts for testing or thousands for assembly lines, our CNC machining capabilities adapt to your needs with stable quality and competitive lead times.

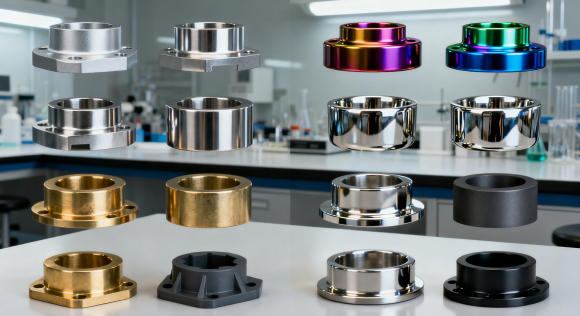

We work with a wide range of metals and plastics—such as aluminum, stainless steel, brass, and engineering plastics—and offer complete surface finishing options including anodizing, plating, polishing, and coating.

Our engineering team provides design feedback and manufacturability advice within 24 hours. By combining experience and technology, we help clients reduce cost, improve part performance, and accelerate project timelines.

In addition to our core industries, we also provide custom CNC machining solutions for sectors such as optics, industrial production, sensors, and communications, ensuring precision and reliability across diverse applications.

Precision components for lenses and systems.

CNC parts for telecommunication devices and infrastructure.

Custom parts for robotic systems and automation.

High-quality parts for manufacturing processes.

Precision components for sensor devices and systems.

Custom designs for unique craft items.

Precision parts for household products and appliances.

Precision components for high-quality instruments.