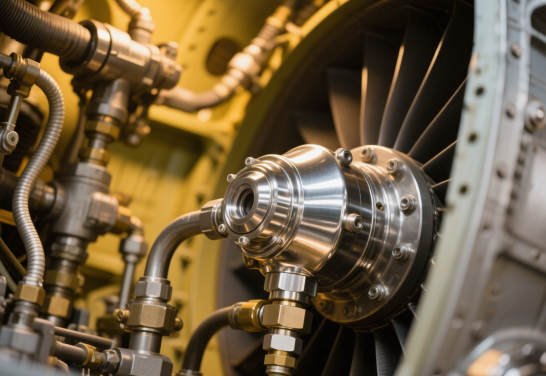

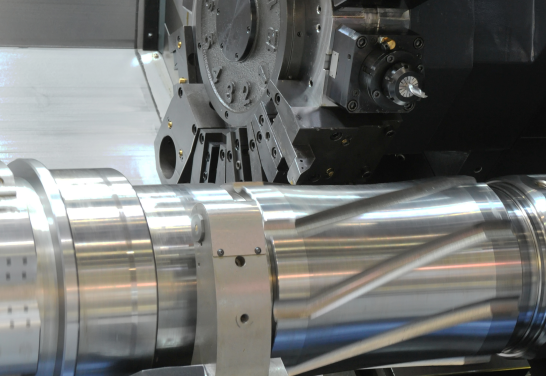

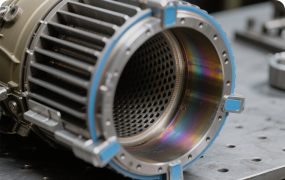

In the aerospace industry, aluminum is among the most widely used metals. As the third most abundant metal on

Earth, aluminum perfectly meets the high standards required in aerospace applications. Its lightweight, high

strength, and good toughness make it ideal for aircraft structural components, engine parts, and aerospace

electronic devices.

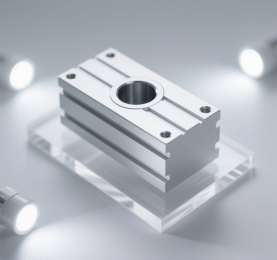

Compared to steel, aluminum has a density of approximately 2.7 g/cm³—only one-third

that of steel—while offering an excellent strength-to-weight ratio, which helps reduce aircraft weight and improve

fuel efficiency and payload capacity. Aluminum also has better machinability than titanium alloys, lower

processing costs, and is easier to apply surface treatments.

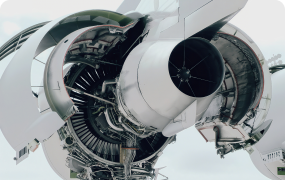

Beyond aluminum, other common aerospace materials include titanium alloys, magnesium alloys, and high-strength

steels. Titanium alloys offer superior strength and corrosion resistance, with a density of about 4.5 g/cm³, but

come with higher cost and machining difficulty. Magnesium alloys are lighter but have limited strength, making

them suitable for non-critical structural parts. High-strength steels provide exceptional strength but are

heavier, typically used in landing gear and power transmission components.

Therefore, aluminum

remains the preferred material in aerospace component manufacturing due to its lightweight, strength, toughness,

cost-effectiveness, and processing flexibility. We provide customized material and machining solutions tailored

to specific part requirements, ensuring reliability and safety even in the most demanding flight environments.