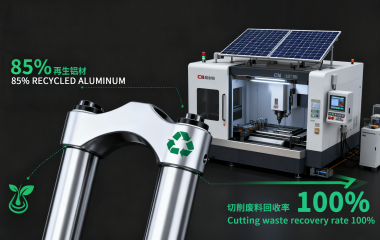

Lightweight to reduce your mental fatigue

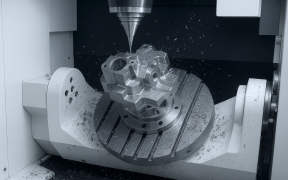

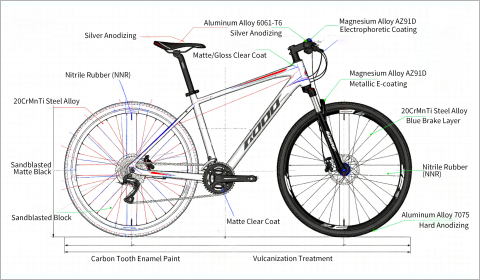

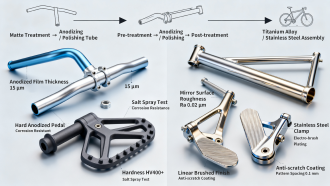

Modern bicycles demand lightweight yet durable parts. CNC machining allows for the production of complex,

high-strength, and precise components that improve performance, safety, and aesthetics.

They are

usually produced from aluminum or other mental/ plastic material with high precision, light weight, and

consistent quality. Common parts include stems, cranks, pedals, hubs, and brake components.