High-quality hydraulic processing for various industries

Hydraulics are an indispensable power source in modern machinery, widely applied in construction machinery,

agricultural equipment, building systems, aerospace, marine engineering, and industrial

automation.

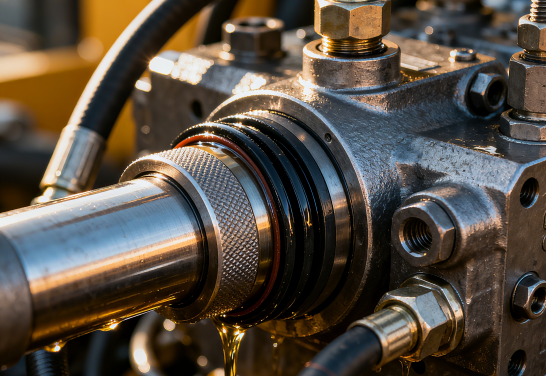

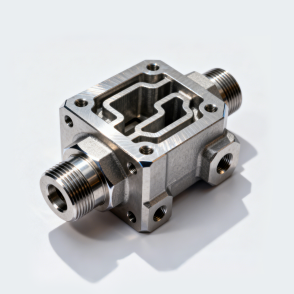

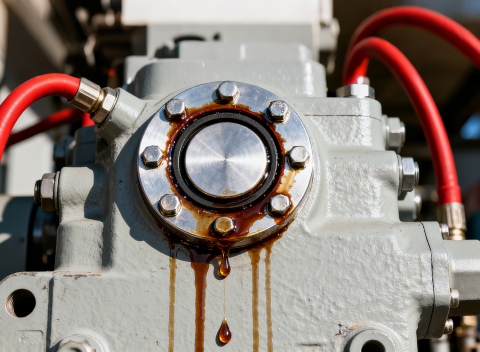

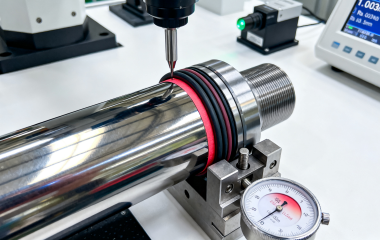

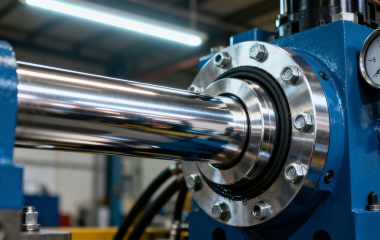

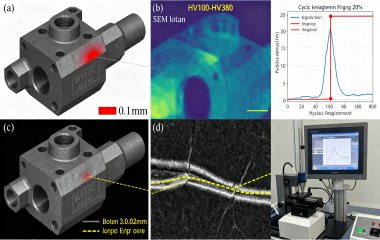

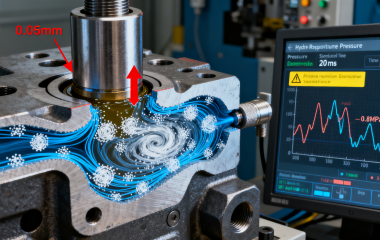

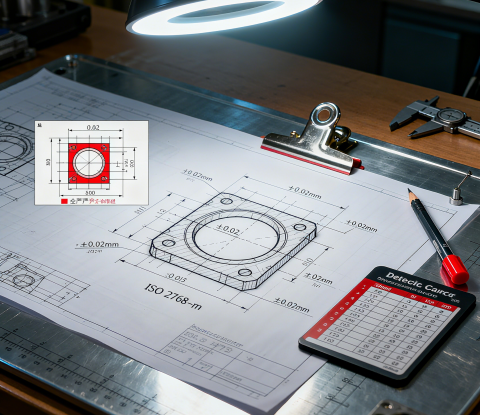

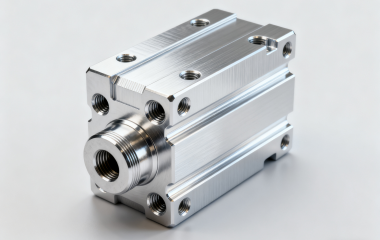

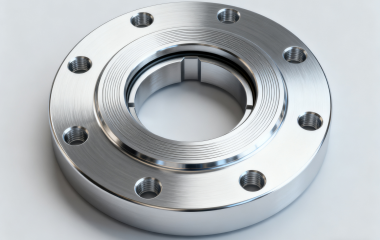

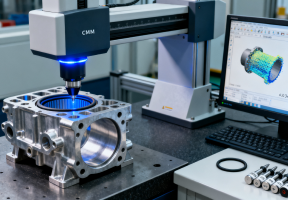

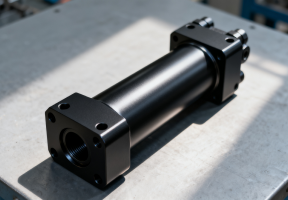

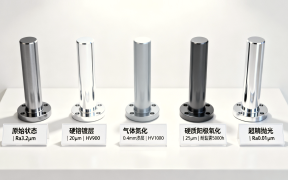

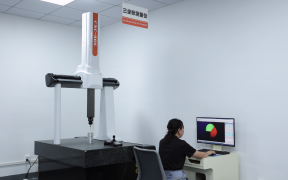

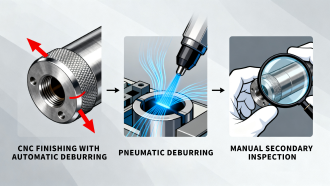

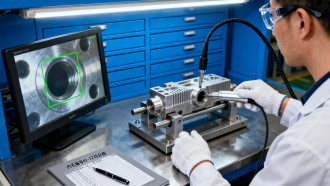

The core components of hydraulic systems must possess high strength, wear resistance,

and corrosion resistance, while their machining precision and reliability directly determine the operating

efficiency and service life of the equipment.