Ride off-road. Race in your own style

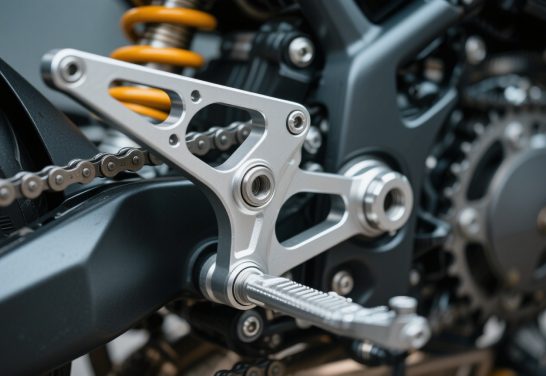

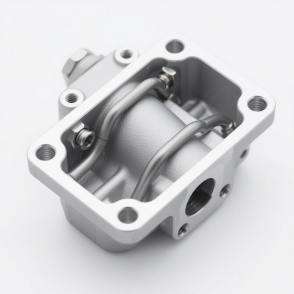

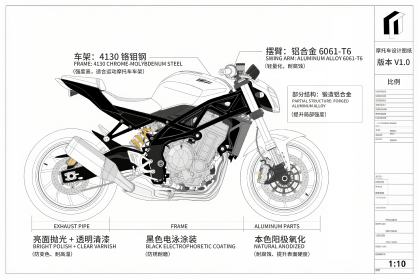

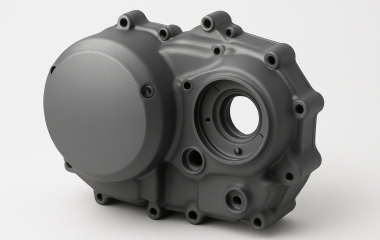

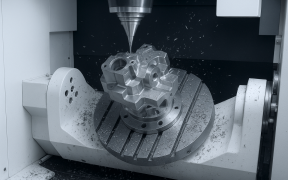

We have extensive experience in motorcycle machining — our precision-crafted parts not only boost overall

performance but also help you choose the right materials and surface finishes.

Off-road motorcycles

are widely used in racing, adventure, and extreme sports, demanding exceptional strength, impact resistance,

and

lightweight performance from their components. These bikes operate at high speeds over dirt, sand, rocks, and

in

rain or snow, with parts enduring constant vibration, impact, abrasion, and temperature changes.