Incoming Quality Control

Incoming Quality Control

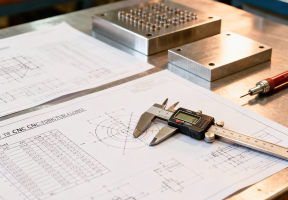

First Piece Inspection

First Piece Inspection

Process Inspection

Process Inspection

At REKO, every project starts with strict material control.

We only source raw

materials from reputable and certified suppliers, and each batch comes with traceable documentation.

Many customers tell us they have experienced this with other suppliers:

Before machining begins, our engineers perform a rigorous review of customer drawings.

Our inspection workflow ensures dimensional stability throughout the entire production process.

Different material with different interval times for inspection

| Material | Inspection time of important size | Full inspection time | Remark | ||

| Intervals Time | Test items | Intervals Time | Test items | ||

| Aluminum | 30 mins | 1. Thread(Ring gauge and Thread gauge) 2. Inner hole(go-no go fixed gauges) 3. Key sizes |

60 mins | All sizes on the drawing | Adjust appropriately according to part size, tolerance, and appearance requirements. |

| Brass | 30 mins | 1. Thread(Ring gauge and Thread gauge) 2. Inner hole(go-no go fixed gauges) 3. Key sizes |

60 mins | All sizes on the drawing | Adjust appropriately according to part size, tolerance, and appearance requirements. |

| Stainless Steel | 15 mins | 1. Thread(Ring gauge and Thread gauge) 2. Inner hole(go-no go fixed gauges) 3. Key sizes |

45 mins | All sizes on the drawing | Adjust appropriately according to part size, tolerance, and appearance requirements. |

| Low carbon steel, iron | 20 mins | 1. Thread(Ring gauge and Thread gauge) 2. Inner hole(go-no go fixed gauges) 3. Key sizes |

45 mins | All sizes on the drawing | Adjust appropriately according to part size, tolerance, and appearance requirements. |

Surface finish plays a major role in final product quality.

Before any part goes to

surface treatment, it must pass a 100% pre-finish inspection.

Remove burrs, tool marks, and sharp edges

Ensure consistent surface roughness (Ra control)

Group parts by material batch to prevent color variation

Confirm dimensional allowance for finishing thickness

All Parts must be fully checked before anodizing, It is to improve surface treatment quality rate.

| Item | NO. | Picture | Material | Color | Before anodizing | Order Qty. | Anodizing Qty. |

| 1 | Front_12x100 (PO1556-1) |

|

AL7075 | Black | Full inspected | 25 | |

| 2 | 90200XX PO1559-1 |

|

AL6082 | Anodized natural layer thickness 15um±5um | Full inspected | 11 | |

| 3 | EX2-T20 (PO1508) |

|

AL6061 | Chemical grinding + anode black | Full inspected | 1000 | |

| 4 | 61315-BVF-T00 PO1545 |

|

AL6061 | Black | Full inspected | 439 | |

| 5 | Leg Part PO1544-2 |

|

AL6061 | Sandblasted 120#+ oxidized black pantone number: Black 6C | Full inspected | 500 | |

Remark:

|

|||||||

|

Consigner/Date:

Approval:

Consignee/Date:

|

|||||||

We will prepare a diagram of the mounting points and inform the surface treatment supplier of the exact positions of the anodized connection points. This will prevent them from mounting the components in the wrong positions, which could cause scratches on the product.

If the parts is with hole, and the hole with very high tolerance request. Will do the first piece anodizing for first checking, Then go ahead for the full order anodizing after first piece approved.

REKO has QC colleague worked in surface treatment factory, To control the quality and ensure the delivery time. REKO's QC will check the dimension in time after surface treatment done at the surface factory.

Color difference control, Check the color according to Color sample or Pantone code.

If the color rejected, will remake the color for the parts or do obsolescence.

Before packaging, every order must pass our strict outbound inspection.

Mixed batches in one shipment

Wrong or missing labels

Scratches from poor protection

Incorrect color or finish

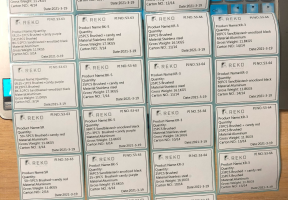

"Three-Step Verification" before dispatch

Clear labeling with part number, batch, and quantity

Visual documentation of each shipment

Customized packaging for high-value components

Before packaging, every order must pass our strict outbound inspection.

Every project begins with a cross-department meeting to review drawings, tolerances, materials, and timelines.

Each batch moves with a unique traveler card for full traceability.

If an issue occurs, REKO provides professional root-cause analysis and preventive actions.

Material, finishing, and heat-treatment partners are scored monthly based on stability, consistency, and delivery performance.

Because we treat quality as a process, not an afterthought.

From materials to

machining,to finishing,to the final delivery-every step is built for zero surprises.

Thanks for understanding, yes I have been very busy with the project! The sample quality I received was good, I was pleased with them, and I truly feel we could order next metal order from You.

Hey, yes the parts were very very good, thank you. I'd like to look at getting 500 of the 20-Blades, as made in this last sample run.

We have just received the package.Everything is ok and the goods look so nice. Thanks for the information you sent is clear and well-arranged.

I'm happy about machining quality and customer service is top! Will send you another inquiries soon.

Trusted by engineers and innovators in 30+ countries.