Technical Advantages of Black Oxide

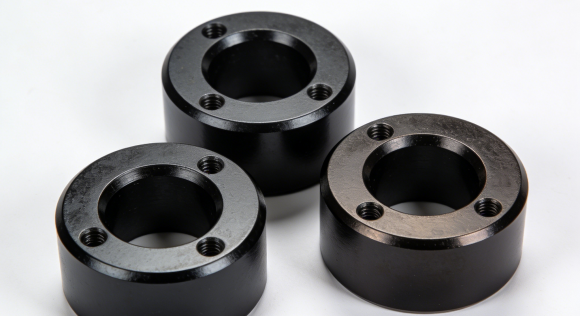

Excellent Corrosion Resistance

Dense, pinhole-free coating protects metal from rust and chemical exposure.

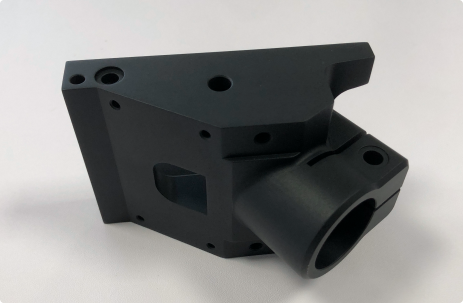

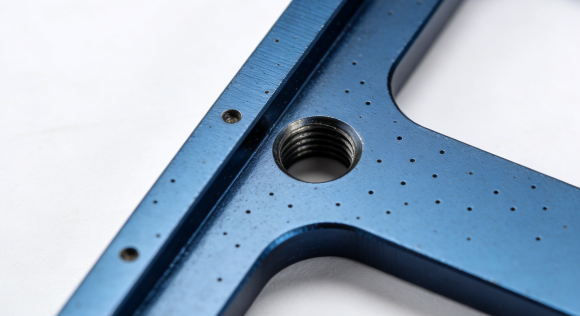

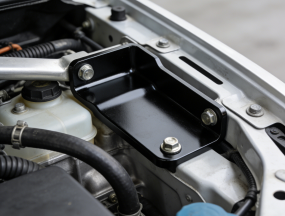

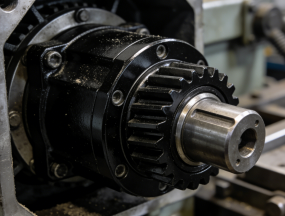

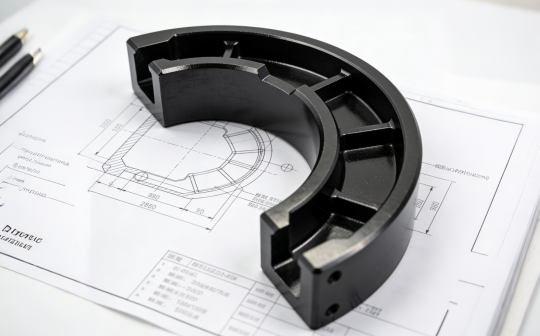

Uniform Coating Coverage

Ensures full coverage on edges, corners, cavities, and threads.

Strong Adhesion

Provides an excellent bonding layer for paint, powder coating, or other finishes.

Thin Controlled Film

Typical thickness 10–35 μm without affecting tight tolerances.

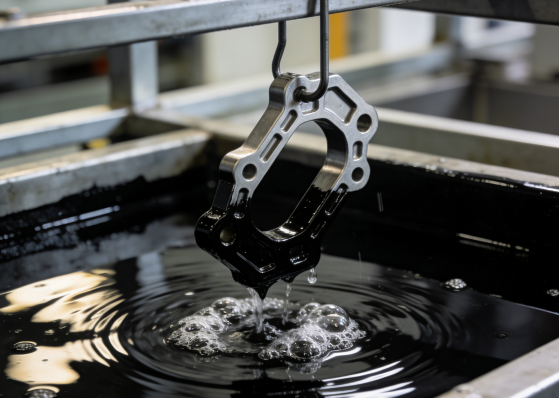

Eco-Friendly Process

Water-based coating, low VOC emissions.