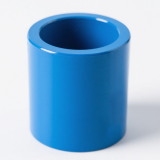

Painting is a versatile and widely used metal finishing technique that provides both protection and aesthetic enhancement for metal surfaces. Appearance ideal for automotive, aerospace, and industrial applications.

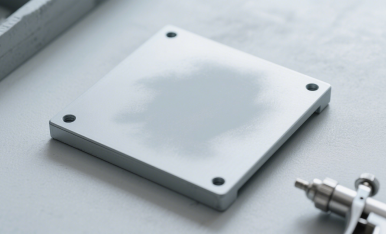

Spray painting involves atomizing liquid paint and applying it uniformly to part surfaces using a spray gun. This process creates a smooth, protective, and decorative coating layer that adheres well when proper priming and surface preparation are applied.

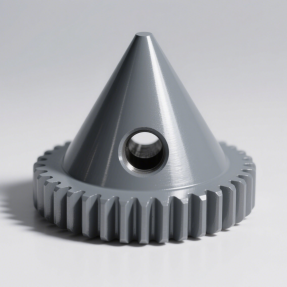

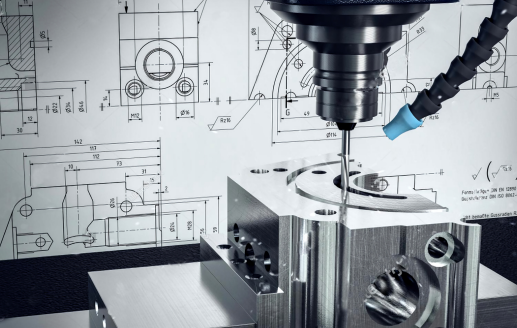

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| 01 |

Degreasing

Removes oils or residues for proper paint bonding.

Typical Parameters:

Alkaline wash at 50–70°C, 5–10 min.

Standards:

In-house PT-SOP-01;

|

Standards:

In-house PT-SOP-01;

|

|

| 02 |

Surface Prep / Sanding

Smooths surface and increases paint adhesion.

Tools:

Sandpaper, abrasive blasting (if needed).

Standards:

In-house PT-SOP-02;

|

Standards:

In-house PT-SOP-02;

|

|

| 03 |

Priming

Enhances paint adhesion, especially on plastics.

Typical Primer:

Epoxy or PU-based primer.

Standards:

In-house PT-SOP-03;

|

Standards:

In-house PT-SOP-03;

|

|

| 04 |

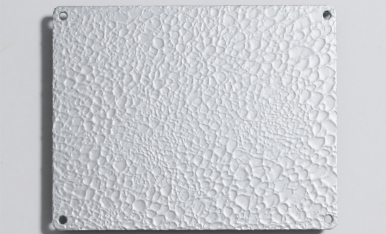

Color Spray Coating

Apply 1–3 layers of paint with uniform coverage.

Finish Options:

Glossy, matte, metallic.

Standards:

In-house PT-SOP-04;

|

Standards:

In-house PT-SOP-04;

|

|

| 05 |

Curing / Baking

Ensures paint hardness and adhesion.

Typical Temp:

60–80°C (plastics), 150–180°C (metals).

Standards:

In-house PT-SOP-05;

|

Standards:

In-house PT-SOP-05;

|

|

| 06 |

Inspection & Touch-Up

Check for defects, rework uneven spots if needed.

Typical Parameters:

Standards:

In-house PT-SOP-06;

|

Standards:

In-house PT-SOP-06;

|

|

| Property | Typical Range |

| Paint Layer Thickness | 10–25 μm |

| Adhesion Standard | ASTM D3359 (cross hatch test) |

| Gloss Level | 5%–90% based on finish type |

| Scratch Resistance | Depends on curing method and paint system |

| Heat Resistance | Up to 120°C (based on paint type) |

Send us your part files or design drawings. Our finishing experts will evaluate the geometry, surface requirements, and production scale to recommend the ideal spray paint process for your CNC machined parts.