Why Do Stainless Steel Parts Need Passivation?

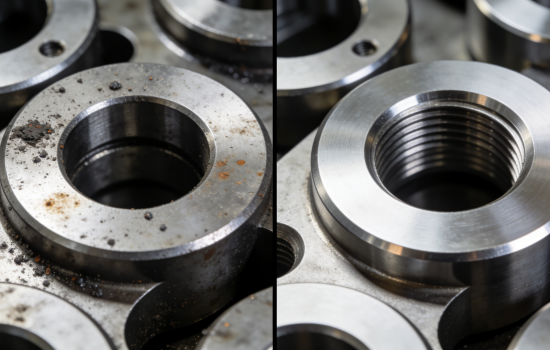

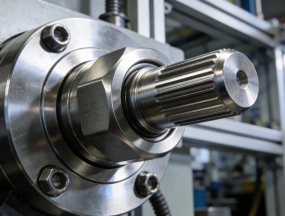

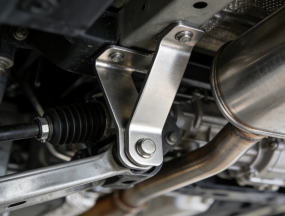

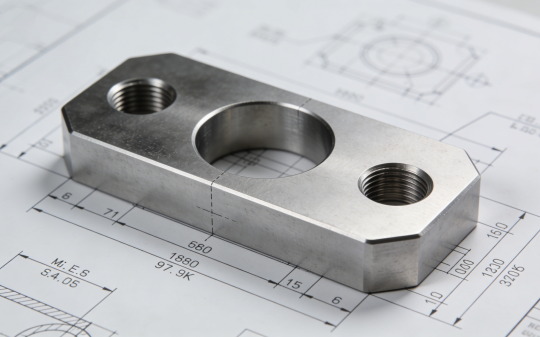

During machining, handling, and storage, stainless-steel surfaces may be exposed to iron, carbon steel particles, cutting fluids, or environmental contaminants. These impurities weaken the natural oxide layer and may lead to:

Passivation removes these contaminants and rebuilds the protective layer, ensuring long-term stability.