Our factory is equipped with modern CNC machines that allow us to handle complex geometries, tight tolerances, and repeatable production.

High-Speed CNC Drilling & Tapping Center with 3+2 Axis Capability

3 Linear Axes + 2 Indexing Rotary Axes (Non-Simultaneous)

170*270*100mm

800 / 400 / 550 mm

Up to 20,000 rpm / 15 kW (BBT30)

±0.008 mm

±0.005 mm

21-Tool Automatic Tool Changer (ATC)

Mitsubishi (Supports 3+2 indexing machining)

Multi-face machining of aluminum and small precision metal parts, complex hole patterns, angled features, and high-efficiency production requiring reduced setups.

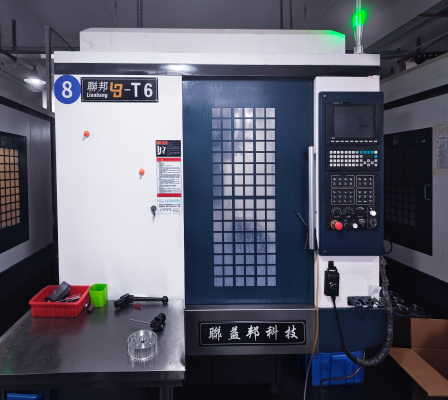

High-Speed CNC Drilling & Tapping Center

3-Axis CNC (X / Y / Z)

580 × 300 × 400 mm

600 / 320 / 550 mm

Up to 20000 rpm / ~8 kW (BT30 spindle)

±0.01 mm

±0.005 mm

21 Tool Automatic Tool Changer (ATC)

SYNTEC

High-efficiency drilling, tapping, and light milling for aluminum and steel parts, suitable for brackets, housings, fixtures, and precision components in electronics, automotive, and general industrial applications.

5-Axis CNC Machining Center (Simultaneous 5-Axis)

5-Axis Simultaneous (X / Y / Z + A / C)

170 × 270 × 100 mm

800 / 480 / 500 mm

Up to 12,000 rpm / ~20 kW (BT40 spindle)

±0.005 mm

±0.003 mm

24-Tool Automatic Tool Changer (ATC)

SYNTEC (Supports true 5-axis simultaneous machining & RTCP)

Simultaneous 5-axis machining of complex geometries, including aerospace components, medical parts, impellers, housings, and high-precision multi-surface parts requiring tight tolerances and reduced setups.

High-Speed CNC Drilling & Tapping Center with 4th Axis Indexing

3 Linear Axes + 1 Indexing Rotary Axis (Simultaneous 4-Axis)

300 / 300 / 300 mm

600 / 400 / 300 mm

Up to 12,000–20,000 rpm / 7.5 kW (BBT30)

±0.008 mm

±0.005 mm

21-Tool Automatic Tool Changer (ATC)

Mitsubishi (Supports 4-axis simultaneous control)

Multi-face drilling, tapping, and light milling of small to medium parts, ideal for circular hole patterns, multi-side features, and high-efficiency batch production with reduced setups.

CNC Turn-Mill Machining Center

4 Axis Configuration (X / Z + C + Y, with live tooling)

Ø300 mm

300 / 98 / 450 mm

Main Spindle: up to 3,000 rpm / ~15kW Live Tooling: up to 4,000 rpm

±0.008 mm

±0.005 mm

12-Station Turret with Live Tools (Radial & axial driven tools supported)

SYNTEC (Supports Y-axis and C-axis interpolation)

One-setup turning, milling, drilling, and tapping of complex rotational parts, suitable for shafts, bushings, housings, connectors, and precision components requiring both cylindrical and milled features.

CNC Slant-Bed Lathe

2 Axis CNC (X / Z)

Ø250 mm

X: 950 mm / Z: 250 mm

Up to ~3,000rpm / ~7.5kW

±0.01 mm

±0.008 mm

8–12 Position NC Turret

SYNTEC

Precision turning of shafts, cylindrical parts, bushings, and medium-size rotational components for automotive, industrial, and mechanical assemblies.

5-axis machining is powerful — but it is not always the best choice.

At REKO, we select the machining method based on part geometry, tolerance, material, and cost efficiency, not on machine complexity.

Many high-precision components can achieve equal or even better accuracy on well-configured 3-axis or 4-axis machines, with shorter setup time, lower risk, and more stable repeatability.

Using a 5-axis machine where it is not necessary increases cost without adding real value to the part.

That's why we reserve 5-axis machining for parts that truly require it — such as complex free-form surfaces, multi-angle features, or tight positional relationships.

This approach allows us to deliver the right process, the right machine, and the right cost for every project.

The QC room is independent from the production area and equipped for precise inspection throughout the manufacturing process.

By controlling quality at every stage, we reduce risks, prevent defects, and ensure each part meets customer drawing requirements.

Materials and parts are clearly identified and stored in designated areas to avoid mix-ups and ensure traceability.

Proper warehouse management helps us maintain stable lead times and reliable delivery for international customers.

The displayed samples allow customers to quickly understand our machining capabilities, surface finish quality, and experience with various materials and processes.

The showroom provides a clear and direct view of our real manufacturing level and quality standards.

We don't aim to be the biggest factory — we focus on being a reliable, responsive, and professional

manufacturing partner.

If you are looking for consistent quality, clear communication, and dependable

delivery, we are ready to support your project.